Ship-to-Shore Container Crane (STS)

Ship-to-Shore Container Cranes (abbreviated as STS) refer to specialized equipment designed for high-efficiency container ship handling at port terminals. As a core asset in modern container hub ports, Wuxin’s STS achieve precise movement along the quayside via a steel-wheel rail travel mechanism and feature a multi-voltage compatible power system (380V–10kV) to adapt flexibly to diverse port grid infrastructures. With optimized operational design, their theoretical handling efficiency reaches 60 natural containers/hour. Wuxin STS comply with the latest GB, FEM, DIN, IEC, and AWS standards, offering safety, stability, customization, low maintenance costs, and energy efficiency.

Key Technical Parameters

Max. Outreach (m) 45

Rated Lifting Capacity (t)

Under Spreader: 35, 41, 60

Under Hook: 45, 50, 65

Lifting Height (m)

Above Rail Level: 12, 16, 18, 20

Below Rail Level: 0-30

Contact Us

- Product Advantages

- Technical Parameters

- Areas of Application

- Options

-

- Commodity name: Ship-to-Shore Container Crane (STS)

- 列表概要: Ship-to-Shore Container Cranes (abbreviated as STS) refer to specialized equipment designed for high-efficiency container ship handling at port terminals. As a core asset in modern container hub ports, Wuxin’s STS achieve precise movement along the quayside via a steel-wheel rail travel mechanism and feature a multi-voltage compatible power system (380V–10kV) to adapt flexibly to diverse port grid infrastructures. With optimized operational design, their theoretical handling efficiency reaches 60 natural containers/hour. Wuxin STS comply with the latest GB, FEM, DIN, IEC, and AWS standards, offering safety, stability, customization, low maintenance costs, and energy efficiency.

<p>Ship-to-Shore Container Cranes (abbreviated as STS) refer to specialized equipment designed for high-efficiency container ship handling at port terminals. As a core asset in modern container hub ports, Wuxin’s STS achieve precise movement along the quayside via a steel-wheel rail travel mechanism and feature a multi-voltage compatible power system (380V–10kV) to adapt flexibly to diverse port grid infrastructures. With optimized operational design, their theoretical handling efficiency reaches 60 natural containers/hour. Wuxin STS comply with the latest GB, FEM, DIN, IEC, and AWS standards, offering safety, stability, customization, low maintenance costs, and energy efficiency. </p> <p> </p> <h3> Key Technical Parameters </h3> <p><strong> Max. Outreach (m) </strong>45</p> <p><strong> Rated Lifting Capacity (t) </strong></p> <p> Under Spreader: 35, 41, 60 </p> <p> Under Hook: 45, 50, 65 </p> <p><strong> Lifting Height (m) </strong></p> <p> Above Rail Level: 12, 16, 18, 20 </p> <p> Below Rail Level: 0-30</p>

1. Spreader Tilting System

The spreader can tilt forward/backward at small angles and rotate horizontally for easier container alignment.

2. Stable Structural Design

Reduces sway, facilitating operation and container positioning.

3. Trolley Drive Options

Trolley can be traction-driven or self-propelled.

4. Smart Lubrication Design

Timed and measured grease replenishment at lubrication points reduces manual maintenance costs.

5. Gale Warning System

Monitors wind speed in real-time, outputting alarm signals, voice prompts, and crane control signals via the control unit.

6. Modular Design

Facilitates factory pre-assembly, reducing on-site installation time.

7. Advanced Craftsmanship & Equipment

Integral main girder fabrication ensures smooth camber curves, effectively reducing trolley rail grinding.

8. Multi-LevelSafety Protections

Inherent crane safety remains our goal. Redundant safety designs and real-time cloud monitoring ensure operational safety.

9. Advanced Tooling Guarantee

Full girder rotation tooling enables flexible turning of large beams for flat-position welding of critical seams.

10. Secondary Sandblasting

Ensures surface cleanliness and roughness meet coating requirements before painting.

11. Truck Anti-Lift

Detects container-truck positional relationships to prevent hooking incidents during lifting.

12. Cab Impact Prevention

Detects truck movement during loading to avoid cab collisions.

13. Electronic Work Zone Barrier

Identifies personnel/objects in restricted areas and enforces motion limits to enhance safety.

14. Anti-Bowling System

Real-time container stack detection prevents collisions during operations.

15. Auto-Correction

Monitors gantry rail deviation and adjusts motor speeds to prevent rail grinding.

16. High Power Factor & Low Harmonic Distortion

Intelligent compensation systems improve power factor, reduce line loss, and optimize power quality.

17. One-Touch Anchoring

Precision positioning + electric anchors enable single-button anchoring.

-

Parameter Name

Recommended Value

Rated Lifting Capacity (t)

Under Spreader

35,41,60

Under Hook

45,50,60

Gantry Gauge (m)

10.5,16,22,25,30

Outreach (m) 15,18,21,23,26,30,35,40,45

Backreach (m) 7.5,10,12,15

Lifting Height (m)

Above Rail Level 10-20

Below Rail Level 5-20

Hoisting Speed (m/min)

Full Load

30

40

60

90

No Load

50

70

100

160

Trolley Speed (m/min)

Full Load

100

180

210

No Load

100

180

210

Gantry Speed (m/min)

Full Load/No Load

25,30

-

Shore-based Container Cranes are primarily used at port and terminal fronts, serving as specialized equipment for efficiently handling container vessels. They operate on steel rails using steel wheels and can be powered by 380V to 10KV electricity.

-

1. Energy Recovery System (Optional): Recovers energy during lowering of loads, reducing energy waste.

2. Remote Control System (Optional): Achieves crane remote control, enabling one operator to handle multiple machines.

3. Intelligent Lubrication (Optional): Allows separate automatic timed-and-measured lubrication at different lubrication points.

4. Smart Online Monitoring System (Optional): Real-time monitoring of operational status (including vibration, temperature rise, etc.) for critical crane components, with data transmission to remote control centers.

Case

Automated Rail-Mounted Container Gantry Crane (ARMG)

Rail-Mounted Container Gantry Crane (RMG)

Rubber-Tired Container Gantry Crane (RTG)

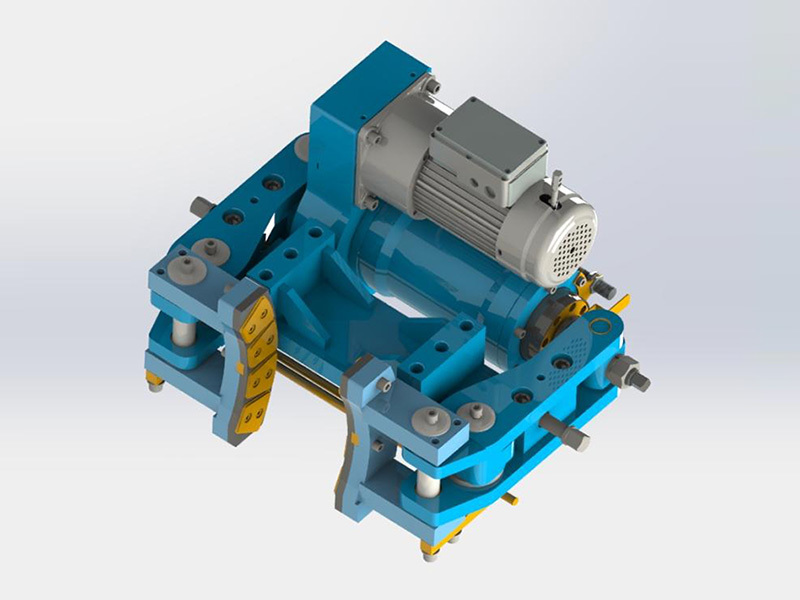

Wheel Clamp

Related products

Contact Us

Please be sure to fill in the information accurately and maintain accessible communication channels. We will contact you as soon as possible.