Bridge-Type Grab Ship Unloaders

Bridge-Type Grab Ship Unloaders are designed for bulk cargo unloading operations from barges and seagoing vessels, serving as core equipment in bulk terminals for discharging commodities such as coal, ore, and grain. Utilizing traditional grab bucket opening/closing and hoisting mechanisms to handle materials, they offer proven reliability, high maneuverability, and minimal maintenance requirements. Bridge-Type Grab Ship Unloaders’ unique advantages—adaptability to diverse cargo types and vessel configurations, lower operational costs, and resistance to damage from wave-induced vessel movements—make them irreplaceable compared to other unloading methods.

Key Technical Parameters

Track Gauge (m)30

Rated Productivity (t/h) 3000

Rated Lifting Capacity (t) 63

Lifting Height (m)

Above Rail Level 30

Below Rail Level 0-30

Contact Us

- Product Advantages

- Technical Parameters

- Areas of Application

- Options

-

- Commodity name: Bridge-Type Grab Ship Unloaders

- 列表概要: Bridge-Type Grab Ship Unloaders are designed for bulk cargo unloading operations from barges and seagoing vessels, serving as core equipment in bulk terminals for discharging commodities such as coal, ore, and grain. Utilizing traditional grab bucket opening/closing and hoisting mechanisms to handle materials, they offer proven reliability, high maneuverability, and minimal maintenance requirements. Bridge-Type Grab Ship Unloaders’ unique advantages—adaptability to diverse cargo types and vessel configurations, lower operational costs, and resistance to damage from wave-induced vessel movements—make them irreplaceable compared to other unloading methods.

<p>Bridge-Type Grab Ship Unloaders are designed for bulk cargo unloading operations from barges and seagoing vessels, serving as core equipment in bulk terminals for discharging commodities such as coal, ore, and grain. Utilizing traditional grab bucket opening/closing and hoisting mechanisms to handle materials, they offer proven reliability, high maneuverability, and minimal maintenance requirements. Bridge-Type Grab Ship Unloaders’ unique advantages—adaptability to diverse cargo types and vessel configurations, lower operational costs, and resistance to damage from wave-induced vessel movements—make them irreplaceable compared to other unloading methods. </p> <p> </p> <h3> Key Technical Parameters </h3> <p><strong> Track Gauge (m)</strong>30</p> <p><strong> Rated Productivity (t/h) </strong>3000</p> <p><strong> Rated Lifting Capacity (t) </strong>63</p> <p><strong> Lifting Height (m) </strong></p> <p> Above Rail Level 30 </p> <p> Below Rail Level 0-30 </p>

Full Cargo Adaptability

Compatible with all bulk materials, from lightweight grains to high-density iron ore.

High-Efficiency Operation

Theoretical productivity reaches 3,000 t/h.

Anti-Sway System

Achieves precise positioning under Sea State 8 condition.

Automation

Supports semi-automatic and fully automatic operations.

Precision Algorithms

Automatic Hold-Searching Algorithm achieves 95% hold volume coverage rate, minimizing hold cleaning efforts.

Vibration Monitoring System

Provides gearbox fault pre-warning to prevent accidents proactively.

Eco-Friendly Operation

Dry Mist Dust Suppression System reduces dust concentration at workpoints to ≤5 mg/m³. Supercapacitor recovers 30% of braking energy.

Safety Protection System

3D Collision Avoidance System,Wind Speed Monitoring & Interlock Control and Emergency Stop Device.

-

Parameter Name

Recommended Value

Rated Lifting Capacity (t)

Under Spreader

16,20,25,32,36.5,45,48,52,63,70

Rated Productivity (t/h)

600,800,1000,1250,1500,1800,2000,2500,3000

Gantry Gauge (m)

12,16,22,30

Effective Outreach (m) 22-45

Lifting Height (m)

Above Rail Level 16-32

Hoisting Speed (m/min)

Hoisting

100

120

160

Closing

100

120

160

Trolley Speed (m/min)

Full Load

150-240

Gantry speed (m/min)

Full Load

20,25

-

1. Machinery suitable for unloading operations from bulk cargo barges and seagoing vessels.

2. Capable of serving a wide range of ship sizes, covering vessels from 2,000 DWT to 300,000 DWT.

3. Employs a bridge-type structure and a high-efficiency grab cycle system, making it particularly suitable for large ports with high throughput.

4. Can handle various bulk materials such as grain, coal, sand/gravel, ore, and wood chips.

-

1. Energy Recovery System (Optional):Recovers energy during lowering of loads, reducing energy waste.

2. Remote Control System (Optional):Achieves crane remote control, enabling one operator to handle multiple machines.

3. Intelligent Lubrication (Optional):Allows separate automatic timed-and-measured lubrication at different lubrication points.

4. Smart Online Monitoring System (Optional):Real-time monitoring of operational status (including vibration, temperature rise, etc.) for critical crane components, with data transmission to remote control centers.

Case

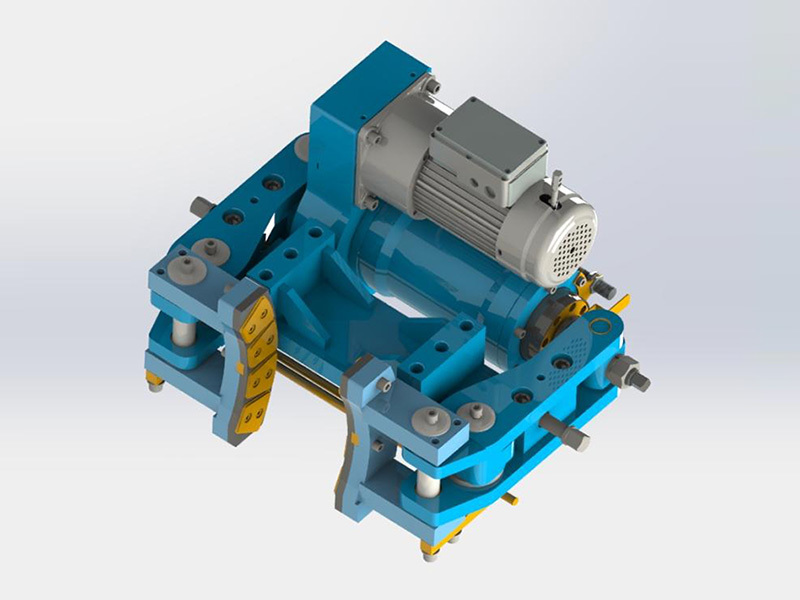

Wheel Clamp

Eco-Friendly Hopper

Related products

Contact Us

Please be sure to fill in the information accurately and maintain accessible communication channels. We will contact you as soon as possible.