Floating Crane

Floating Cranes refer to heavy-duty lifting equipment installed on floating vessels, combining the high-efficiency operation of portal cranes with the mobility advantages of floating platforms. Utilizing the floating vessel as their carrier, they move freely across water bodies, adapting to tidal variations, complex hydrological conditions, and environments without fixed docks, making them a core lifting solution for marine engineering projects.

Key Technical Parameters

Max. Working Radius (m) 20-40

Rated Lifting Capacity (tons)

Hook: 10-80

Under Container Spreader: 35/41

Grab Bucket: 10-50

Lifting Height (m)

Above Rail: 10-30

Below Rail: 5-15

Contact Us

- Product Advantages

- Technical Parameters

- Areas of Application

- Options

-

- Commodity name: Floating Crane

- 列表概要: Floating Cranes refer to heavy-duty lifting equipment installed on floating vessels, combining the high-efficiency operation of portal cranes with the mobility advantages of floating platforms. Utilizing the floating vessel as their carrier, they move freely across water bodies, adapting to tidal variations, complex hydrological conditions, and environments without fixed docks, making them a core lifting solution for marine engineering projects.

<p>Floating Cranes refer to heavy-duty lifting equipment installed on floating vessels, combining the high-efficiency operation of portal cranes with the mobility advantages of floating platforms. Utilizing the floating vessel as their carrier, they move freely across water bodies, adapting to tidal variations, complex hydrological conditions, and environments without fixed docks, making them a core lifting solution for marine engineering projects.</p> <p> </p> <h3> Key Technical Parameters </h3> <p><strong> Max. Working Radius (m) </strong> 20-40 </p> <p><strong> Rated Lifting Capacity (tons) </strong></p> <p> Hook: 10-80 </p> <p> Under Container Spreader: 35/41 </p> <p> Grab Bucket: 10-50 </p> <p><strong> Lifting Height (m) </strong></p> <p> Above Rail: 10-30 </p> <p> Below Rail: 5-15 </p>

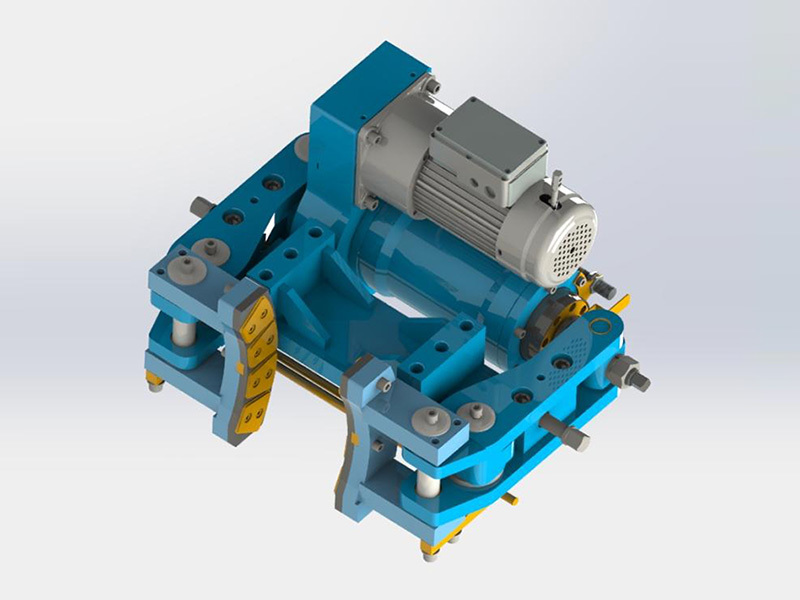

1. Unique Design of Slewing Bearing that Enables Crane-Synchronized Lifespan

Our decades-accumulated machining expertise and membership on China's Boom Crane Standardization Committee ensure the slewing bearing – the most critical mechanical component of portal cranes – achieves identical operational lifespan as the entire machine.

2. Low-Center-of-Gravity Design

The high-boom, low-slewing-platform design concept lowers the center of gravity of portal cranes, significantly enhancing overall machine stability.

3. Special Steel Wire Rope Reeving with Low-wear Design

Utilizing same-direction parallel winding, this method significantly reduces wire rope wear, extends service life by over 20%, and lowers maintenance and replacement costs.

4. Quick-Change Spreader System

The quick-change interface enables seamless switching among grabs, hooks, and container spreaders within 3-5 minutes.

5. Full Electric Drive

Eco-friendly operation with 380V–20kV power compatibility

6. Steel Rail Travel System

Forged steel wheels support higher loads with minimal wear, eliminating frequent wheel replacements and slashing maintenance costs

7. Multi-Level Safety Protections

Intrinsic crane safety remains our core objective. The redundant design of multiple safety mechanisms,combines real-time data tracking via cloud-based monitoring systems to ensure operational safety.

8. High-Efficiency Handling

Bulk Cargo: Up to 1,200 t/h

Containers: Up to 30 TEU/h

9. High Efficiency and Energy Conservation

Continuous operation reduces interruptions, eliminating secondary transport links compared to traditional processes, thereby lowering energy consumption and costs.

10. Automated Operation System

Portal cranes memorize material loading/unloading positions and operation paths. Combined with grab anti-sway, precision positioning, and collision avoidance algorithms, this enables fully automatic grab operations.

11. Anti-Sway Grab Control System

Modeling of the portal slewing system enables calculation of grab swing angles. Intelligent control regulates slewing and luffing speeds to eliminate swing, achieving effective sway elimination.

12. Energy Regeneration System

Energy regeneration system converts electrical energy generated during load descent or motor deceleration and feeds it back into the grid, achieving energy recovery to meet energy-saving and emission-reduction objectives.

13. Energy Recovery System

Stores electrical energy generated during load descent or motor deceleration in battery banks or supercapacitors, releasing it during subsequent operations. This enables energy reuse while reducing the entire system's input power demand.

14. High Power Factor & Low Harmonic Distortion

Incorporating active harmonic filtering and reactive power compensation technology to raise power factor, reduce line losses and optimize electrical power quality.

-

Main Technical Parameters of Floating Cranes

Basic Parameters

Rated Lifting Capacity (t)

Hook

10, 16, 20, 25, 30, 35, 40, 50, 63, 80

Under spreader (container) 35/41

Grab

10, 16, 20, 25, 30, 35, 40, 45, 50

Lifting Height (m)

Above Deck

10-30

Below Deck

5-15

Maximum Working Radius (m)

20-40

Minimum Working Radius (m)

8-13

Speed Parameters

Hoisting Speed (m/min)

20-60

Luffing Speed (m/min)

20~60

Slewing Speed (r/min)

1/1.2/1.5

-

Suitable for port cargo handling, offshore wind turbine installation, bridge construction, and heavy lifting of large structural components.

Grab

Container spreader

Hook

Electromagnetic spreader

-

1. Lifting Attachments: Optional hook, grab, container spreader, electromagnetic lifting device, hook beam, C-hook for steel coils.

2. Smart Systems: Optional cloud monitoring, video surveillance, remote control, condition monitoring, intelligent lightning protection, automatic fire suppression, spreader auto-follow system.

3. Energy-saving Systems: Energy feedback system, energy recovery system.

4. Bulk Cargo Receiving Systems: Mobile hopper, fixed hopper, traction-type hopper.

Case

Single-Jib Portal Crane

Four-link Portal Crane

Grab Bucket Portal Crane

Fixed Crane

Wheel Clamp

Eco-Friendly Hopper

Related products

Contact Us

Please be sure to fill in the information accurately and maintain accessible communication channels. We will contact you as soon as possible.