Goliath Gantry Crane

Goliath Gantry Crane refers to core lifting equipment for hull block assembly and heavy lifting operations, featuring ultra-high load capacity and precision positioning accuracy. Through coordinated operations of upper and lower trolleys, it meets the demands of mega-component tandem lifts and hull block flipping, making it indispensable in large-scale shipyards. Equipped with a dual-track synchronous travel mechanism, it moves along dock rails to adapt to diverse lifting tasks. Select models include basic anti-sway devices and load monitoring systems to enhance operational safety.

Key Technical Parameters

Gauge (m) 180

Rated Lifting Capacity (t) 1000

Lifting Height (m)

Above Rail: 85

Below Rail: 20

Contact Us

- Product Advantages

- Technical Parameters

- Areas of Application

- Options

-

- Commodity name: Goliath Gantry Crane

- 列表概要: Goliath Gantry Crane refers to core lifting equipment for hull block assembly and heavy lifting operations, featuring ultra-high load capacity and precision positioning accuracy. Through coordinated operations of upper and lower trolleys, it meets the demands of mega-component tandem lifts and hull block flipping, making it indispensable in large-scale shipyards. Equipped with a dual-track synchronous travel mechanism, it moves along dock rails to adapt to diverse lifting tasks. Select models include basic anti-sway devices and load monitoring systems to enhance operational safety.

<p>Goliath Gantry Crane refers to core lifting equipment for hull block assembly and heavy lifting operations, featuring ultra-high load capacity and precision positioning accuracy. Through coordinated operations of upper and lower trolleys, it meets the demands of mega-component tandem lifts and hull block flipping, making it indispensable in large-scale shipyards. Equipped with a dual-track synchronous travel mechanism, it moves along dock rails to adapt to diverse lifting tasks. Select models include basic anti-sway devices and load monitoring systems to enhance operational safety. </p> <p> </p> <h3> Key Technical Parameters </h3> <p><strong> Gauge (m) </strong>180</p> <p><strong> Rated Lifting Capacity (t) </strong>1000</p> <p><strong> Lifting Height (m) </strong></p> <p> Above Rail: 85 </p> <p> Below Rail: 20 </p>

1. Multi-Lifting-Point Balance Control Technology

Eliminates deformation during large segment hoisting.

2. Precision Motion Control

Three-coordinate positioning system and anti-sway algorithms suppress load swing.

3. Intelligent Operation Capability

Vision positioning system enhances positioning accuracy.

4. Anti-Collision System

LiDAR + millimeter-wave radar 3D monitoring enables early warning and braking.

5. Dynamic Wind Load Compensation

Improves gantry crane wind resistance.

6. Green Technology

Supercapacitors recover 30% of braking energy.

-

Parameter

Recommended Value

Rated Lifting Capacity (t)

Upper Trolley (Main Hoist) Under Hook

50*2,60*2,75*2,100*2,125*2,2x150,2x200,2x300,2x400,2x500

Lower Trolley (Main Hoist) Under Hook

60,75,100,150,200,250,300,400,500

Lower Trolley (Aux. Hoist) Under Hook

10,20,3,50,75

Lifting Capacity (t)

Tandem Lift (Two Trolleys) 100,120,150,200,250,300,400,,500,600,800,1000

Segment Turning 100,120,150,200,250,300,400,,500,600,800,1000

Gantry Gauge (m)

50,55,60,70,80,90,100,120,150,180

Lifting Height (m)

30,40,50,60,75,85

Hoisting Speed (m/min)

Upper Trolley (Main Hoist) Full Load

1-10

No Load

2-20

Lower Trolley (Main Hoist) Full Load

1-10

No Load

2-20

Lower Trolley (Aux. Hoist) Full Load

10-30

No Load

10-50

Trolley Speed (m/min)

Upper Trolley (Full Load) Full Load

25-40

Lower Trolley (Full Load) Full Load

25-40

Gantry Travel Speed (m/min) Full Load

20-30

-

Primarily used in shipyards (dry docks, building berths, etc.) for hoisting and rotating hull sections. Equipped with steel travel wheels and operable with power supply voltages ranging from 380V to 10kV.

-

1. Intelligent Systems (Optional): Cloud-based monitoring, video surveillance, remote control, condition monitoring, intelligent lightning protection, automatic fire suppression.

2. Energy-Saving Systems: Regenerative feedback system, energy recovery system.

Case

Single-Jib Shipyard Crane

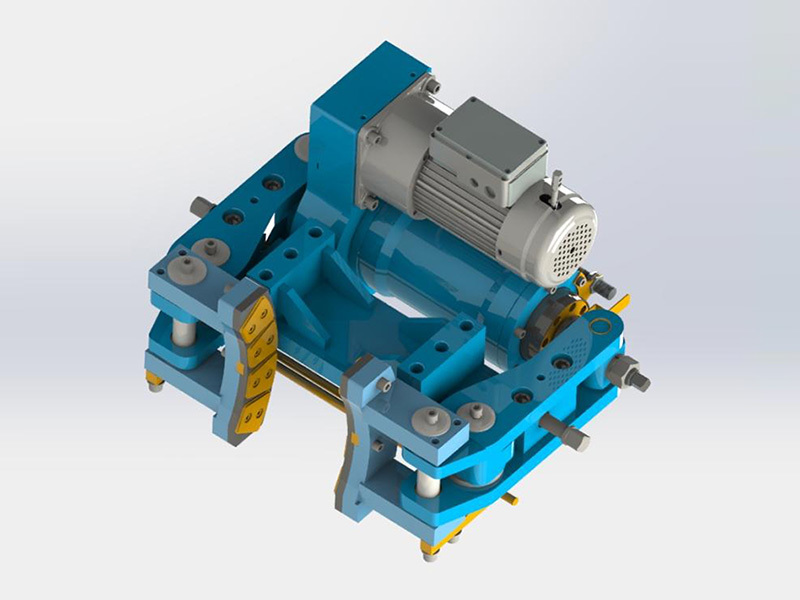

Wheel Clamp

Related products

Contact Us

Please be sure to fill in the information accurately and maintain accessible communication channels. We will contact you as soon as possible.